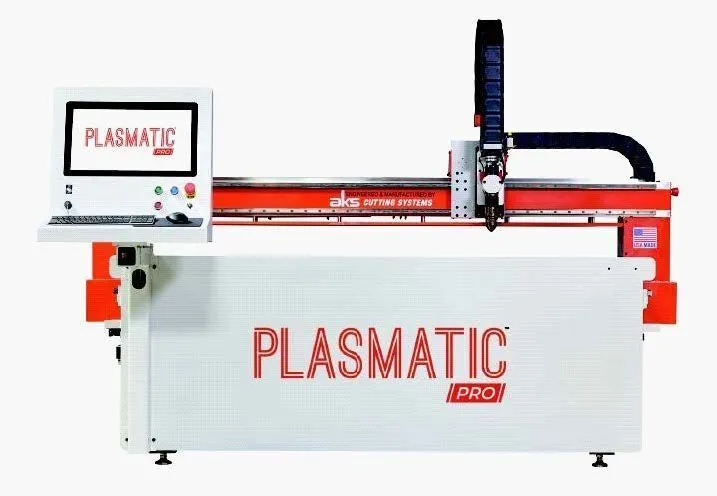

Designed as an upgraded version of the acclaimed PLASMATIC, the PLASMATIC Pro sets a new standard in production-grade CNC plasma cutting machines. It delivers exceptional performance, ease of operation, and unparalleled precision that you won’t get with competitors’ products.

The PLASMATIC Pro is highly customizable, just like all of our machines. With countless options available, you can create the perfect machine for your operation. Our team is standing by to help you find the best options for your business. Contact us today to learn what’s best for you.

The PLASMATIC™ Pro from AKS Cutting Systems offers a range of customizable features, making it adaptable to various cutting needs. One of its standout features is the adjustable height water table, which allows the water level to be raised and lowered to suit different cutting tasks. This flexibility optimizes fume suppression and debris management by adjusting the water level based on material thickness or specific cutting requirements. As falling parts are caught by the built-in catch trays, slag and debris fall through and collect below. These accumulated materials need to be periodically scooped out to maintain a clean and efficient cutting environment.

The PLASMATIC™ Pro integrates Hypertherm’s SureCut Technology, which enhances cutting efficiency and precision. Notable features include True Hole, which ensures smooth, round holes in mild steel, Rapid Part, which optimizes cutting speed and cycle times, and Sensor Torch Height Control (THC), which maintains an optimal cutting distance from the workpiece for consistent results. Additionally, the ProNest CAD/CAM software helps optimize part nesting, reducing material waste and improving overall cutting efficiency.

With servo motors and a helical rack and pinion drive system, the PLASMATIC™ Pro delivers smooth, precise motion, reducing vibration and enhancing cut quality. The machine offers multiple Hypertherm power supply options, including the MaxPro200, XPR series, and Powermax SYNC, allowing customers to choose the right power source for their needs. Available table sizes include 5x10 feet and 6x12 feet options. Additionally, the machine comes with an optional oxy-fuel torch, providing even greater versatility for cutting thicker materials. Together, these features make the PLASMATIC™ Pro an ideal choice for businesses seeking efficiency and precision in their plasma cutting operations.

Motion Accuracy: 0.005” per 3 feet of motion

Travel Speed: 1200 ipm

Screen Size: 19-inches

Max Cut Depth: 3 inches

Max Cut Width: Up to 6

Max Cut Length: Up to 12

AKS "PLASMATIC PRO" Plasma Cutting System with 5' x 10' Plate Cutting Area - Down Draft

• Hypertherm™ EDGE® Connect CNC Controller Unit

• Hypertherm™ Phoenix® Operating Software

• Hypertherm™ XPR170 Plasma Power Supply Unit (480v)

• Hypertherm™ XPR170 Plasma Torch Cutting Head

• Hypertherm VWI Console

• Hypertherm™ Mild Steel Start-Up Kit for Plasma Unit

• Laser Pointer for Plate Alignment and Location Finding

• Heavy Duty "Unitized" Table with Removable/Replacable Slat Design

• Multi-Zone Air Downdraft Table with Automatic Zone Control with Removable Lift Out Slag Pans

• 10' X-Axis Dual Synchronized Drives with Helical Rack & Pinion

• 5' Y-Axis Bridge Single Drive with Helical Rack & Pinion

• Advanced Torch Height Control (THC) Lifter, Servo Driven Lead Screw with Arc Voltage Control System

• Magnetic Torch Breakaway

• Local License of ProNest 2025™ Base Software, "Plasmatic" Package including: Advanced Plasma Post Processor, Automatic Nesting, & 1st Year Maintenance Program for perpetual software license

• Onsite Installation & Training by certified AKS Technician

• One Year AKS New Machine Warranty (Parts & Labor)

• Participation in AKS Cutting Systems Elite Edge Consumable Program

• Lifetime Phone Support from AKS for All Service and Cutting Support, With purchase of Hypertherm™ consumables from AKS Cutting Systems

We use cookies to improve your experience. Privacy Policy.