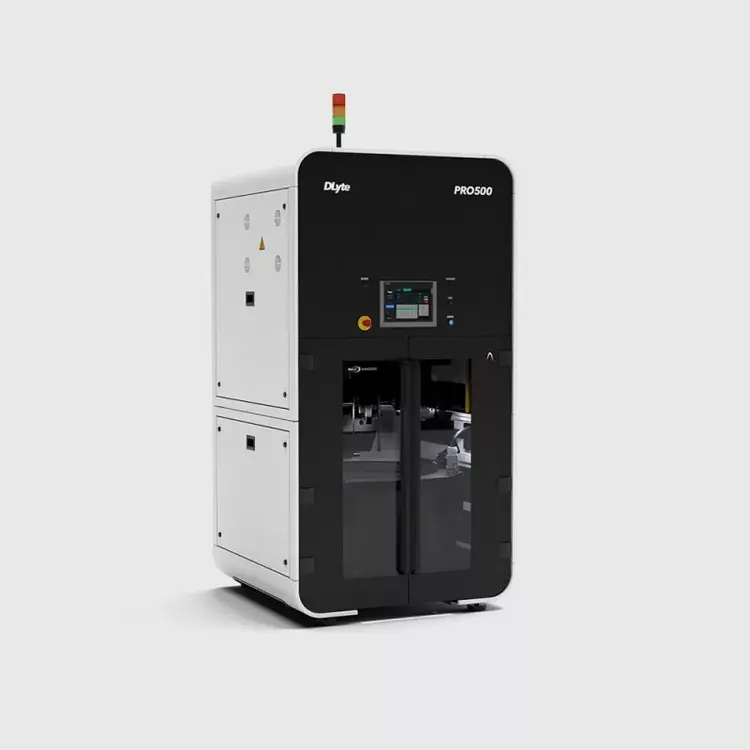

PRECISE METAL SURFACE FINISHING FOR MASS PRODUCTION

DLytePRO500 Hybrid is the most advanced, powerful and versatile

metal surface finishing equipment on the market specially designed

for finishing parts using dry electropolishing or hybrid process in

mass production.

Workbowl and holders are not included.

DIMENSION

- Machine dimensions 1,300 x 2,770 x 1,380 mm

CAPACITY

- Electrolyte capacity 250 l

- Holder + piece area Ø200 x 540 mm (x8)

- Work piece area Up to Ø200 x 200 mm (x8)

- Weight 20 kg (work piece(s) + holder) (x8)

MACHINE WEIGHT

- DLyte PRO500 weight 1600 kg

- Tank with electrolyte 400 kg

ELECTRICAL (1)

- Rated power from 11,5 KW to 25 KW (2)

- Short-circuit breaking capacity (ics) 6 kA

- Rated voltage 400 Vac ± 10% (3P+N+GND)

- Frequency 50 - 60 Hz

- Rated current 35 A

- Full load current 40 A

- Grounding connection TN system

- Earth leakage current > 10 mA (3)

AIR

- Air supply (Main line) 6 - 7 bar (air connector Ø10 mm)

- Air flow (two lines) 1,900 l/min (4)

- Air inlet pipe Ø20

- Air quality (ISO 8573-1:2010) 6. 4. 4 (ISO 8573-1:2010)

DISTILLED WATER

- Water supply Connection (Ø10 mm)

- Water tank 16 l

TEMPERATURE

- Operating 5°C to 35 °C

- DLyte PRO500 storage -10°C to + 70°C

- Electrolyte storage 5°C to 40°C (max. 24 months)

PROTECTION INDEX

- Machine IP20

- Electric cabinets and peripherals IP22

NOISE

- Holder vibrators OFF (EN ISO 11202) <70 dB

- Holder vibrators ON (EN ISO 11202) 74 dB (1 m); <70 dB (7m)

We use cookies to improve your experience. Privacy Policy.