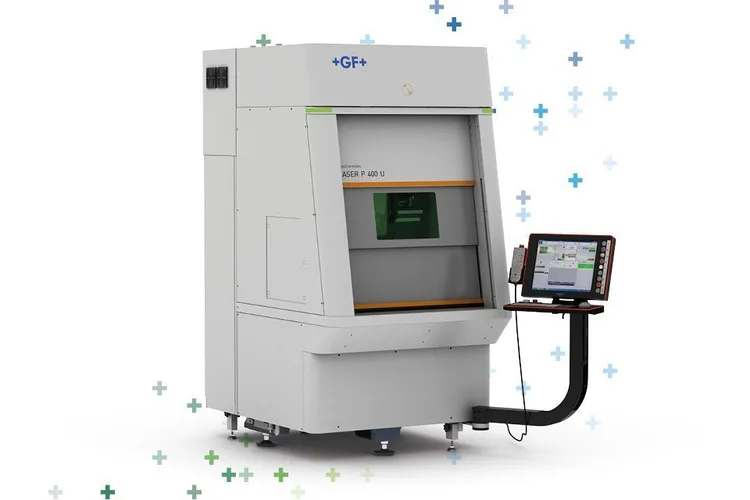

The LASER P 400 series is full digital, all-in-one three (3) or five (5) axis LASER solution packing outstanding quality and efficiency in the smallest possible footprint. This machine is designed to excel in 2D and 3D texturing, structuring, engraving, and marking on small parts, like medical implants, watchmaking and jewelry pieces, small inserts, cutting tools and micro machined work pieces. Our unique All-In-One dedicated software package provides you with the necessary tools to perform all kinds of texturing, structuring and engraving jobs, from the office to the shop floor, from day one.

LASER P 400 series highlights:

- Configurable with a choice of laser sources:

● Nanosecond 30W, 50W FlexipulseTM.

● Femtosecond 20 W IR, 40W Infrared, or 40W IR/GR FlexipulseTM.

- Basic machine ready to integrate multiple combinations of nanosecond and/or femtosecond laser sources. - Marking field up to 105 x 105 mm with an F160 f-Theta lens.

- Automatic lens calibration.

- High productivity and quality thanks to SMARTSCAN and SMARTPATCHTM.

- The machine is automation-ready, left or right loading.

- Machine travel axes X, Y, Z: 600 x 400 x 300 mm.

- rConnect for remote service and productivity monitoring (TüviT Trusted Product Certificate).

Dimension of complete equipment *

1227 x 1659 x 2379 mm

Machine weight (machine only)

2400 kg

Floor space (machine only)

2.04 mq

Maximum workpiece dimensions 3Ax/5Ax

600 x 400 x 300 / Ø 120 x h 120 mm

Maximum workpiece weight 3Ax/5Ax

50/4 kg

Table size

680 x 400 mm

Travel X/Y/Z

400 x 600 x 300 mm

Rotary 4/5 axis **

A 115°-105°/B 360° mm

Laser sources

Multi-Laser sources: nanosecond and/or ultrashort pulsed laser **

Power consumption

Electrical: 3 x 400 Vac + ground; 6 kVA Pneumatic: 6 bars 500 l/min

We use cookies to improve your experience. Privacy Policy.